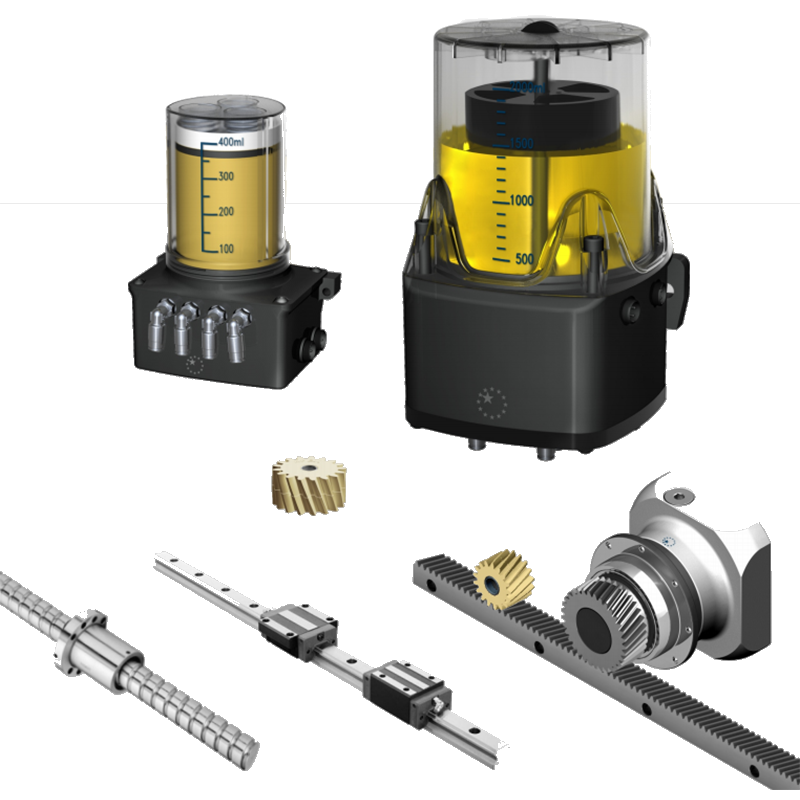

Racks and Pinions, Smart Lubrication Systems

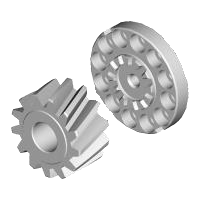

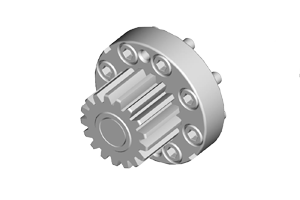

A series – Curvic Plate

Module: 2 / 3 / 4 / 5 / 6 / 8 / 10

Max. torgue: 14 090 Nm

A series – Curvic Plate

Module: 2 / 3 / 4 / 5 / 6 / 8 / 10

Max. Torgue: 10 800 Nm

Accessories

straight, rectangular, with check valve, for filling lubricant, connecting for PA tubes

B series – welded plate

Module: 2 / 3 / 4 / 5 / 6 / 8

Max. torgue: 3 250 Nm

B series – welded plate

Module: 2 / 3 / 4 / 5 / 6 / 8

Max. torgue: 3 680 Nm

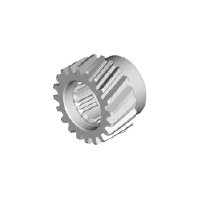

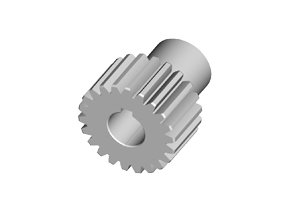

C series – standard pinion

Module: 2 / 3 / 4 / 5

Max. torgue: 5 815 Nm

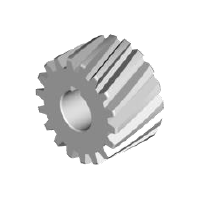

D series – internal grooving DIN5480

Module: 1,5 / 2 / 3 / 4 / 5

Max. torgue: 3 455 Nm

E / F series – keyway

Module: 1,5 / 2 / 2,5 / 3

Max. torgue: 1 010 Nm

E series – with keyway

Module: 2 / 3 / 4 / 5 / 6 / 8 / 10

Max. torgue: 16 920 Nm

F series – with keyway for pen / CP system

Pitch: 5 / 10 / 13,33

Max. moment: 1 400 Nm

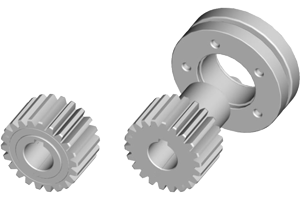

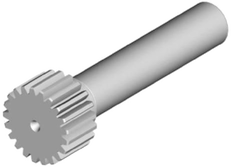

G series – shaft with keyway, with hub

Module: 2 / 3 / 4 / 5 / 6

Quality: Q4 / Q5H / Q5 / Q6 / Q6M / Q8H / Q8 / Q8 / Q9 / Q10

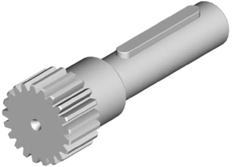

H series – smooth shaft

Module: 2 / 3 / 4 / 5 / 6

Quality: Q4 / Q5H / Q5 / Q6 / Q6M / Q8H / Q8 / Q8 / Q9 / Q10

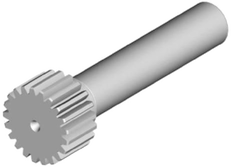

H series – smooth shaft

Module: 2 / 3 / 4 / 5 / 6

Quality: Q4 / Q5H / Q5 / Q6 / Q6M / Q8H / Q8 / Q8 / Q9 / Q10

Lubricants

NLGI Grade 2; high temperature resistance -30 ° C + 140 ° C; kinematics viscosity from 15 cSt for 50 cSt / 40 ° C

Lubrication pinions

straight, helical - right and left

module M1-M12

special porous polyurethane material

straight and angle mounting shafts

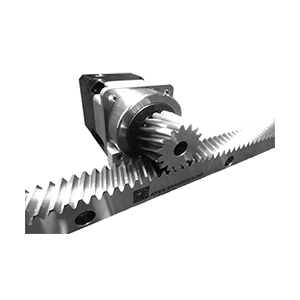

Racks with Helical Teeth

Module: 1 / 1,5 / 2 / 2,5 / 3 / 4 / 5 / 6 / 8 / 10 / 12

Quality: 4 / 5H / 5 / 6 / 6M / 8 / 10

Racks with Straight Teeth

Modul: 1 / 1,5 / 2 / 2,5 / 3 / 4 / 5 / 6 / 8 / 10 / 12

Quality: 4 / 5H / 5 / 6 / 6M / 8 / 9 / 10

Smart Lubrication System

support for up to 40 lubrication positions, lubrication frequency setting, ATEX certification, LUG 400, LUG 2000