APEX DYNAMICS CASE STUDY VI: APEX DYNAMICS AS A LEADER IN LINEAR DRIVE

27. 6. 2019 | Vansichen Linear Technology was one of the first in Europe to be intensively engaged in the movement of robots with a load, and in recent years, thanks to its technological lead, it has recognized its excellent market position. Engineers from this company were able to devise technology and systems for the heaviest and most powerful FANUC robot. APEX DYNAMICS contributed to this project by supplying its AFR180 type planetary gearboxes.

VANSISCHEN LINEAR TECHNOLOGY

The success of Vansichen in the field of linear drives began at a time when the company received an ambitious demand from the customer to mount the robots on the ceiling to which the customer needed linear motion. Vansichen has taken on the challenge of implementing the contract and has come up with a design solution that allows this requirement. This job has become a demonstration, giving the company the ability to move robots under any circumstances. As a result, robot manufacturers have begun to find their way and then work with Vansichen as most of the robots now operate in environments that exceed their range. For FANUC, Vansichen has prepared a full catalog for both standard and non-standard linear motion applications.

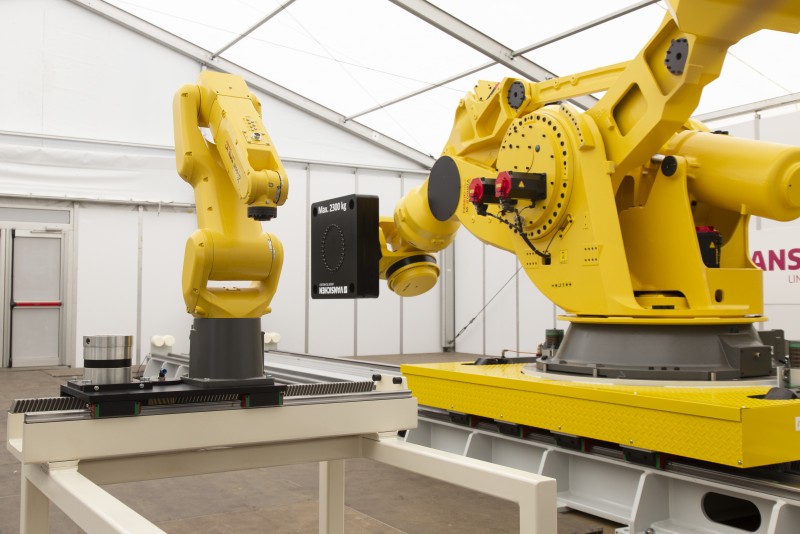

FANUC M-2000iA / 2300 DEMO TRACK INTRODUCTION

This year in May, Vansichen presented its latest development and project called Demo Track (FT65) with the latest FANUC articulated robot M-2000iA / 2300, which is an impressive 11 tons. The Demo Track and the 2,300 kilograms robot were first introduced in the Netherlands.

“Products with a weight of about 2 tons often have large dimensions, which is a big problem for a standard robot range. The sample track is 12 meters long, but we are able to build these tracks up to 100 meters long, ” says Vime-Vansichen. They are usually used for the construction of rails of up to 12 meters in length, but due to the large weight of the FT65 and the potential load, rails of 6 meters were used. FANUC robots are available with more than 100 species, offering the greatest variability in every conceivable industry in the world. The payload of this type of robot is up to 2.3 tons and the operating range is 3,7 m.

Intensive collaboration also took place not only between Vansich, FANUC and APEX DYNAMICS, but also with Pollers, which took care of the robot frame. In the case of linear robots, these are in tens of meters.

DUAL DRIVE AND TRANSMISSION FOR LONG LENGTH

For the FT65, we delivered two very powerful 180-degree angle planetary gearboxes of the AFR series. Double-drive was chosen for higher accuracy, because the thicker FANUC robot actuators are not yet available. The AFR 180 delivers up to 1,980 Nm of torque and 18,000 N power.

It is very impressive to see the final installation, and how the technology moved forward again in 2019. The 11 ton robot handles, places and operates with a load of almost 2.5 tonnes. The accuracy of each linear motion is 0.1 mm at a speed of 1 m / s. This robot can withstand 100% workload 24 hours a day, 7 days a week.

ABOUT VANSICHEN LINEAR TECHNOLOGY

The company was founded in 1993 by current CEO Maxim Vansichen. Initially, they began to represent a number of German linear technology brands in Belgium and Luxembourg. More than a quarter of a century later, the company began designing its own solutions and products as an extension of a range of high quality brands they distribute. Today, the Hasselt-based company (Limburg) has more than 20 employees and is one of the leading providers of linear technology. For videos, please visit our Media tab.

If you are interested in more information, do not hesitate to contact us at info@apexdynaczech.cz or call +420 577 663 877.