APEX DYNAMICS CASE STUDY II: Using the Design Tool in Machine Development and Production!

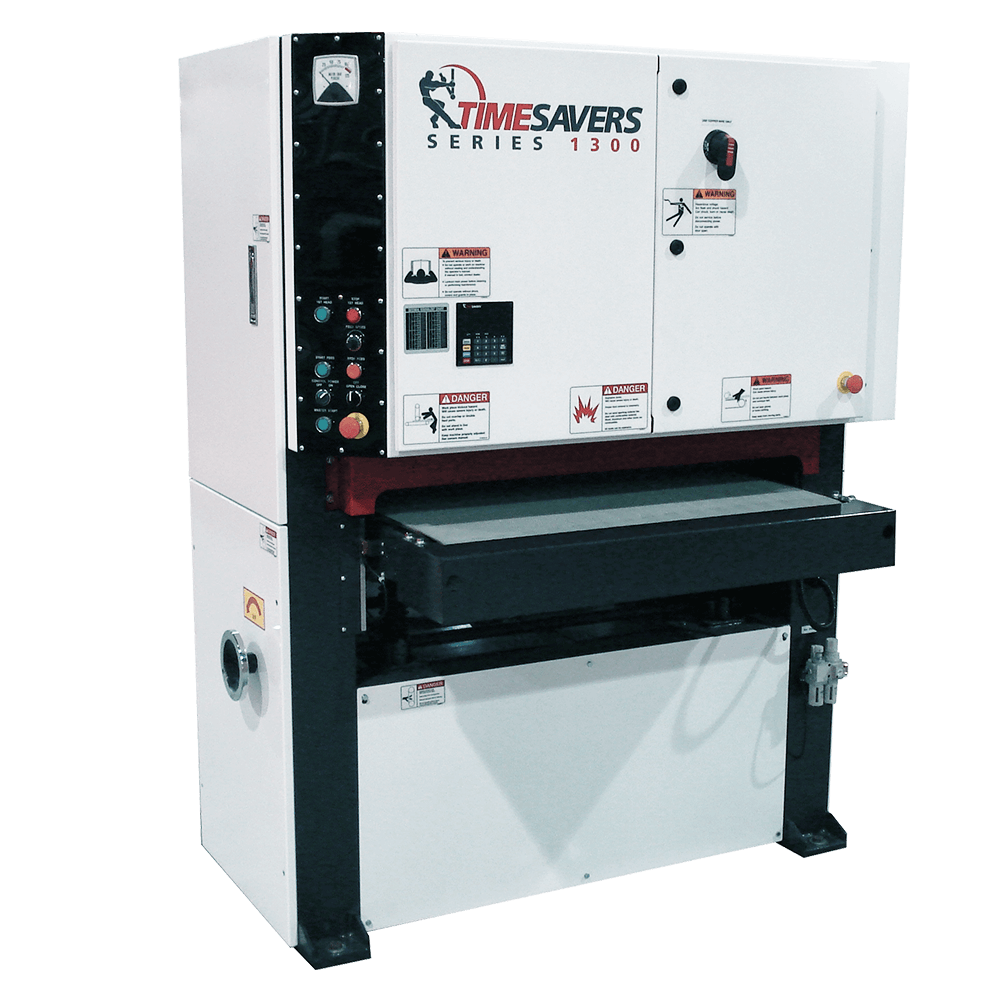

29. 4. 2019 | Easy and quick selection of a servomotor gearbox combination? Timesavers recently used the design tool to select a matching gearbox for a new deburring machine. The specialized manufacturer of metal finishing and deburring machines could immediately download all drawings and send her request. Together with the team from Apex Dynamics they could then come to the optimal solution for this application. In this article we will discuss the application and choice of Timesavers extensively.

Gearbox for new sanding machine to be developed

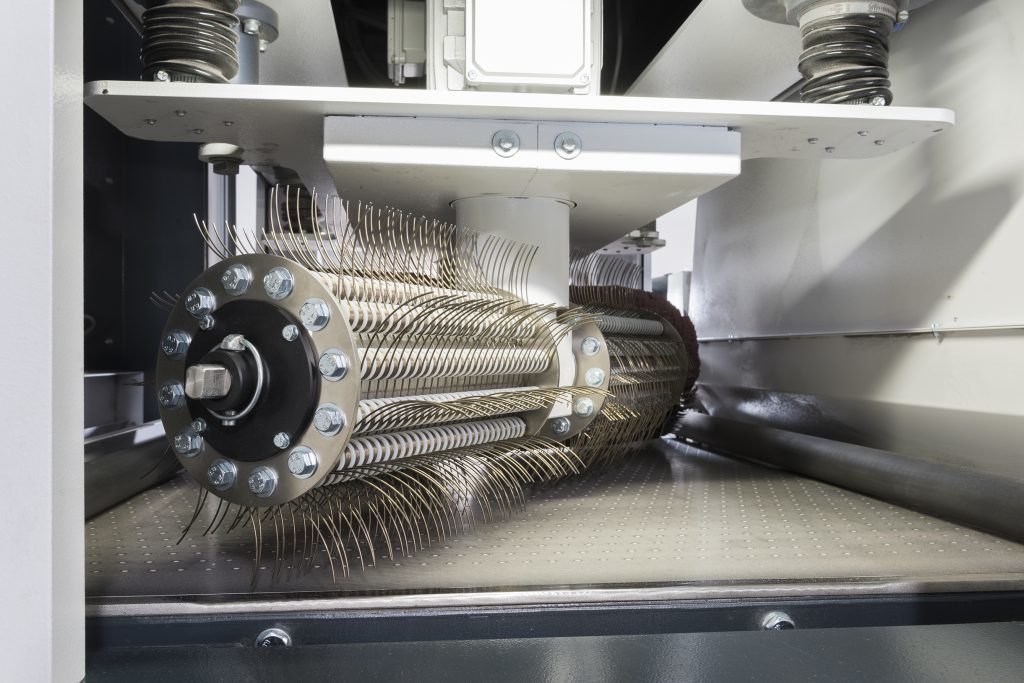

Timesavers contacted APEX DYNAMICS for a new development. The gearboxes are used, among other things, to adjust the roller (including the sanding belt) in height and to adjust the machine opening. The load varies a lot, the gearboxes are used in machines with a working width of 600 mm up to and including 2100 mm.

The combination of servomotors in combination with the gearboxes from APEX DYNAMICS was made easily: Previous experience was already good and the engineering of the right combination of servomotors and gearbox was simple:

“Using the design tool we were able to select the right servo motor, and from there you are intuitively guided through the selection process. In the final step, the servomotor specifications, the gearbox specifications and the order code are shown. Moreover, you can immediately download the drawings without any login.”

For this application Timesavers has used the AB high-end planetary gearbox and an ATB spiral bevel gearbox with double output shaft. As an extra service, APEX DYNAMICS assembles the gearboxes to the servomotors.

Nothing secret in APEX DYNAMICS!

Therefore, you can download company information – 2D drawings, 3D models, catalogs and other important product information. Using the online configuration tool is very intuitive and is the most popular one. The design tool can also be used to select precision racks and pinions.

About Timesavers

Timesavers originated in 1939, when Arie van der Linden started a repair shop for woodworking machines in Rotterdam. In 1953 the company began to specialize in long belt sanders and rubber band sanders. In the year 1963, wide band sanders were added to the range of sanders that were produced. From 1970 the company expanded with machines for metal, aluminum, carbon and stainless steel.

Twenty years later the company was taken over by the American company Timesavers, and in 1996 Timesavers International B.V. was established. Timesavers International B.V. focused on activities worldwide, with the exception of North America. The company became a global market leader in grinding and sander machines for wood and metal applications.

Timesavers was as much focused on both wood and metal until 2000. The decision was then made to focus on producing metal finishing and deburring machines. By 2003, the company became the market leader in metal deburring and finishing with wide band machines, while also developing a new high-precision grinding machine. This is suitable for calibrating up to 0.02 mm exactly.

A noteworthy achievement is the winning of the prestigious REDDOT Award for industrial design 2016. Today, Timesavers works from three locations: in Minneapolis, USA where most of the woodworking machines are manufactured, a branch in Goes where medium, heavy and special machines are built, and a branch in Taiwan where the standard machines are built.

With unparalleled service and support, more than 50,000 machines in the field and factory-trained independent dealers and agents, you can be assured that Timesavers can offer the best finishing machines in the world and is ready for the future!

With unparalleled service and support from experienced APEX DYNAMICS technicians, Timesavers can easily stand up for the high quality of its machines and focus on their further development. If you want to learn more, visit our website or contact our specialists directly at support@apexdynaczech.cz or call +420 602 891 880.

You can also find videos from Timesavers in our Media – Video section.